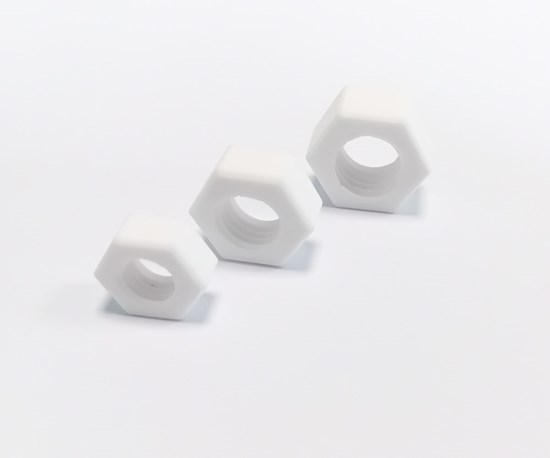

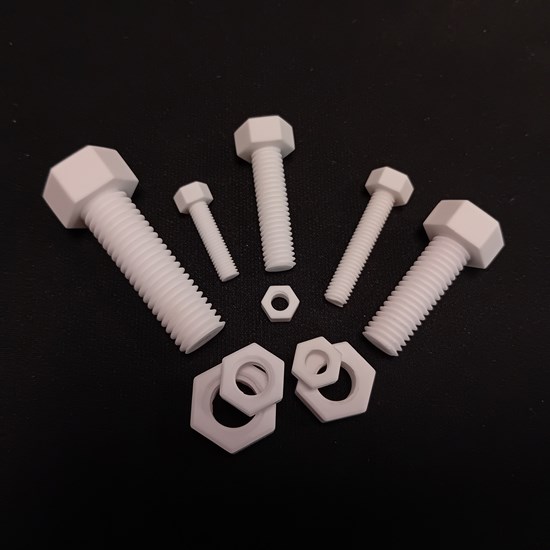

Ceramics are known for their high hardness, just below that of diamond on the Mohs scale. Ceramic screws, nuts and bolts offer exceptional resistance to abrasion, wear and surface damage. This makes them ideal for applications where components are subjected to frictional or abrasive forces.

Alumina is highly resistant to corrosion and chemical attack. It can withstand exposure to various acids, alkalis and corrosives without degrading.

Ceramics are excellent electrical insulators. Ceramic screws, nuts and bolts do not conduct electricity and are therefore suitable for applications where electrical insulation is required, such as in electronic devices or high voltage equipment.

Compared to metal components, ceramic screws and nuts are lightweight. This property is advantageous in applications where weight reduction is a priority, such as in the aerospace or automotive industries, where minimizing the overall weight of components is critical to fuel efficiency and performance.

They are used in all environments where their unique combination of properties, including high temperature resistance, hardness, corrosion resistance and electrical insulation, is essential. As in the Aerospace sector, in the Medical sector being non-magnetic, completely inert at an environmental level and thanks to the anti-interference properties.

Also in the naval sector for resistance to acids, alkalis and corrosion, to extend the useful life of the equipment in which they are used.

Cookie policy

Cookie policy